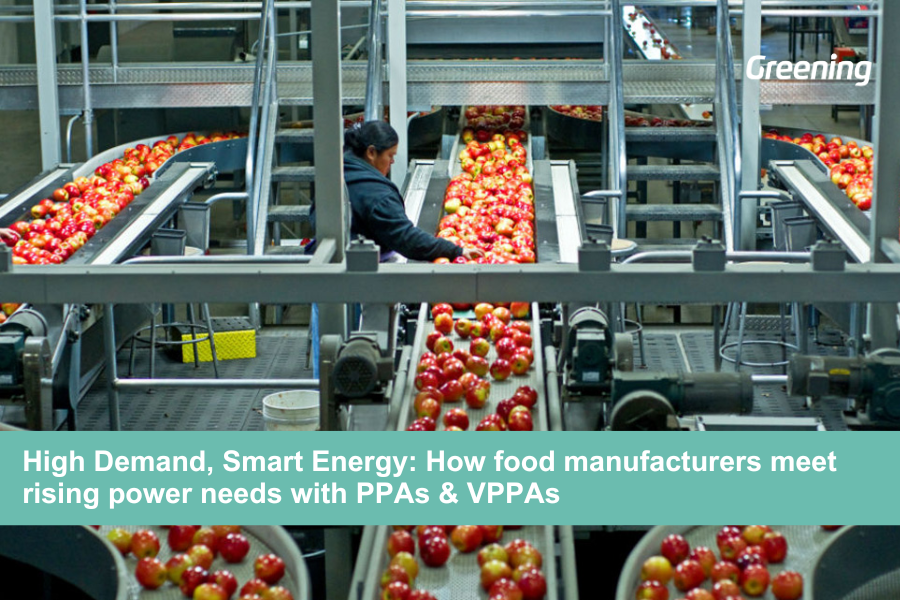

As demand surges, food manufacturers can secure reliable power and cut emissions with tailored renewable energy agreements.

Food production facilities are among the most energy-intensive operations in the industrial landscape. Refrigeration, freezing, cooking, packaging, and 24/7 production cycles require a constant, high load of electricity. As demand continues to rise, many manufacturers face a dual challenge: controlling energy costs while maintaining operational reliability.

Pressures beyond costs

The challenge is not only financial. Food and beverage manufacturers are under increasing pressure to meet ESG targets, comply with stricter reporting standards, and respond to growing consumer demand for sustainable products. At the same time, any interruption in power supply can result in production losses, inventory spoilage, and significant financial setbacks.

In this context, energy is no longer just a utility, it’s a strategic driver of competitiveness.

PPAs & VPPAs: Energy stability

Power Purchase Agreements (PPAs) and Virtual Power Purchase Agreements (VPPAs) have become essential tools for food manufacturers looking to secure clean, cost-stable, and reliable energy.

- Cost Control: By locking in long-term energy pricing, PPAs and VPPAs protect facilities from the volatility of wholesale energy markets.

- Sustainability Leadership: Both solutions provide measurable reductions in energy-related carbon emissions, supporting companies in achieving ESG goals and meeting supply chain expectations.

- Operational Reliability: Onsite solar PPAs can directly power production facilities, while VPPAs connect manufacturers with large-scale renewable projects that ensure dependable generation capacity.

Local Potential, Global Impact

In regions like the U.S. Midwest and SPP South, home to some of the country’s largest food production hubs, the combination of abundant solar and wind resources with strong industrial demand creates an ideal environment for renewable energy adoption. Partnering through PPAs or VPPAs allows food manufacturers to benefit from these resources without the burden of upfront capital investment.

Turning Energy Appetite into Competitive Advantage

For food production facilities, the path forward is clear: energy strategies must deliver lower costs, stronger sustainability credentials, and reliable power supply. PPAs and VPPAs are uniquely positioned to meet all three, ensuring that energy becomes a driver of growth, not a barrier.

Navigating 2025’s Energy Pressures

With electricity prices fluctuating and federal incentives shifting, 2025 is proving to be a pivotal year for industrial energy strategies. For food and beverage manufacturers, this means making decisions today that will define cost structures, sustainability performance, and operational resilience for years to come. Those who act early by adopting PPAs or VPPAs are not only hedging against risk but also positioning themselves as leaders in a market where energy reliability and environmental responsibility are becoming decisive competitive factors.

Is your food production facility ready to take control of rising energy demands?

Contact us at info.us@greening-group.com to explore how a tailored PPA or VPPA strategy can power your operations efficiently and sustainably.